Zhongshan micro team is brave and persevering forward, To cooperate withnew energy, fluorosilicon chemical industry, pesticide, basic chemicalindustry, pharmaceutical enterprises to carry out industrial microanti-technology innovation, and make new achievements in the new micro reactiontechnology.

01

To exploreand promote industrial microreactor technology with 5s store of ZhejiangZhonghong

Offline 5Sstore is a practical measure of ZhongKong's values. It realizes thetransformation from control system to overall solution, from passive responseto active demand discovery and prediction, and from industry 3.0 to industry3.0+4.0. With the concept of "Industrial partner", it providescustomers with 24-hour service. With more flexible and efficient resource allocationand collaboration mechanism to provide customers with more timely and moreclose to the needs of sustainable services. After the industrial micro reactorwith high capacity, high performance and benefit has gained a good reputationin the operation of large-scale enterprises, it may usher in the application ofuniversal micro reactor in the large-scale production of non-rapid reaction.

02

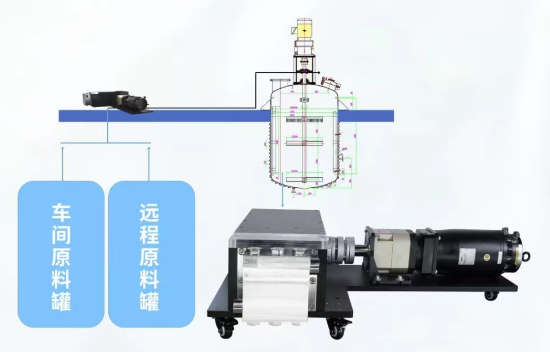

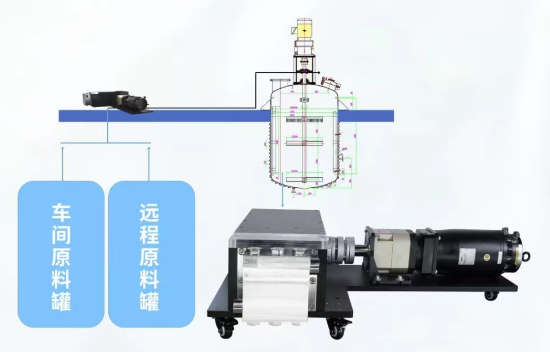

Linear flow constant pump changes the design of fine chemical workshop

In July 2022, the linear flow constant metering pump (Maximum flow30L/min) independently developed by Zhongshan Microreactor team has thecharacteristics of low pulse, second to set flow, 1-100% full flow to achieveaccurate feeding, etc. It has been innovatively applied in the traditionalprecision drip process of fine chemical workshops, perfectly solving theone-button drip process, ensuring a stable reaction temperature, and at thesame time, Compared with traditional metering tank drops, it saves investmentand space. For a 5-50m3 reactor, several tons and several sets of supportingdrip metering tanks need to be equipped, and a supporting weighing module orflowmeter is required. Zhongshan micro inverse flow constant flow pump caneliminate the supporting metering tanks in the workshop, and directly addaccurate drip to the reactor from a floor below 6m. The use of linear flowconstant current pump, chemical workshop layout becomes loose, the temperatureof the reactor becomes more stable, saving the feeding time.

03

Zhongshan Microreactor provide innovation service for top 500 chemicalenterprises

The CiushanGlobal R&D Center of Yantai Wanhua Chemical Group Co., Ltd. has ascientific research team composed of hundreds of doctors, committed to theinnovative research of new products and new processes, and has a long-termdemand for low-cost and high-throughput industrial micro reaction.

JiangsuYangnong Chemical Co., LTD., entrusted Zhongshan Micro reverse synthesisprocess innovation, including Shenyang Sinochem Pesticide Chemical Research andDevelopment Co., LTD., Jiangsu Youjia Plant Protection Co., LTD., JiangsuYoushi Chemical Co., LTD., Liaoning Youchuang Plant Protection Co., LTD.

GuangzhouTianci High-tech Materials Co., Ltd. attaches great importance to scientificand technological innovation, and also pays special attention to the researchof micro-continuous flow technology in the field of new energy materials.

ShandongWeifang Runfeng Chemical Co., Ltd. attaches great importance to the researchand development of new technology and new process in order to build the supplyability of active drug. Green and advanced continuous micro reverse process isof great significance to the strategic layout of the enterprise in the future.

ZhongshanWeifang is committed to working with domestic fine chemical leading enterprisesto promote the continuous fine chemical industry, automatic production, newproduct process development, basic chemical process improvement, from theprocess source optimization conditions, improve reaction mode, optimize unitoperation, achieve raw material consumption reduction, pollutant emissionreduction, improve the atomic economy of chemical production, to achieve cleanproduction of chemical process.

04

Solve chemical reactions with viscosity

Traditionalmicroreactors have limitations for solid-containing reactions, medium-speedreactions, and reactions in viscous systems (including polymerization). Throughthe continuous technical innovation and equipment improvement of the team, thecomplete set of micro reaction technology of Zhongshan Micro reaction hasachieved a technical breakthrough on this basis. For part of the chemicalreaction system with solid content and viscosity <2000mPa.s, stableoperation can be achieved.

05

High throughput microreactor, Reduce the investment of micro reactionequipment

Due to the thin section and small volume of the flow passage, the productioncapacity of a single set of equipment of the industrial micro-reactor isultimately limited. At present, Zhongshan Zhi 'an has been able to provide abatch of silicon carbide micro-reactor with a volume of >3L/ piece ofcorrosion-resistant alloy industrial micro-reactor and a volume of >2L/piece. Taking a nitrification reaction as an example, the reaction time takes 1minute to complete the transformation. If the flux needs to be 15000m3/ year(24000 tons/year), the liquid holding capacity of the complete set of equipmentneeds to be 35L. With ZSMR microreactor, 10~20 modules can be adopted inseries, covering an area of only 12m2, to realize unmanned automatedproduction.

Zhongshan micro team is brave and persevering forward, To cooperate withnew energy, fluorosilicon chemical industry, pesticide, basic chemicalindustry, pharmaceutical enterprises to carry out industrial microanti-technology innovation, and make new achievements in the new micro reactiontechnology.

01

To exploreand promote industrial microreactor technology with 5s store of ZhejiangZhonghong

Offline 5Sstore is a practical measure of ZhongKong's values. It realizes thetransformation from control system to overall solution, from passive responseto active demand discovery and prediction, and from industry 3.0 to industry3.0+4.0. With the concept of "Industrial partner", it providescustomers with 24-hour service. With more flexible and efficient resource allocationand collaboration mechanism to provide customers with more timely and moreclose to the needs of sustainable services. After the industrial micro reactorwith high capacity, high performance and benefit has gained a good reputationin the operation of large-scale enterprises, it may usher in the application ofuniversal micro reactor in the large-scale production of non-rapid reaction.

02

Linear flow constant pump changes the design of fine chemical workshop

In July 2022, the linear flow constant metering pump (Maximum flow30L/min) independently developed by Zhongshan Microreactor team has thecharacteristics of low pulse, second to set flow, 1-100% full flow to achieveaccurate feeding, etc. It has been innovatively applied in the traditionalprecision drip process of fine chemical workshops, perfectly solving theone-button drip process, ensuring a stable reaction temperature, and at thesame time, Compared with traditional metering tank drops, it saves investmentand space. For a 5-50m3 reactor, several tons and several sets of supportingdrip metering tanks need to be equipped, and a supporting weighing module orflowmeter is required. Zhongshan micro inverse flow constant flow pump caneliminate the supporting metering tanks in the workshop, and directly addaccurate drip to the reactor from a floor below 6m. The use of linear flowconstant current pump, chemical workshop layout becomes loose, the temperatureof the reactor becomes more stable, saving the feeding time.

03

Zhongshan Microreactor provide innovation service for top 500 chemicalenterprises

The CiushanGlobal R&D Center of Yantai Wanhua Chemical Group Co., Ltd. has ascientific research team composed of hundreds of doctors, committed to theinnovative research of new products and new processes, and has a long-termdemand for low-cost and high-throughput industrial micro reaction.

JiangsuYangnong Chemical Co., LTD., entrusted Zhongshan Micro reverse synthesisprocess innovation, including Shenyang Sinochem Pesticide Chemical Research andDevelopment Co., LTD., Jiangsu Youjia Plant Protection Co., LTD., JiangsuYoushi Chemical Co., LTD., Liaoning Youchuang Plant Protection Co., LTD.

GuangzhouTianci High-tech Materials Co., Ltd. attaches great importance to scientificand technological innovation, and also pays special attention to the researchof micro-continuous flow technology in the field of new energy materials.

ShandongWeifang Runfeng Chemical Co., Ltd. attaches great importance to the researchand development of new technology and new process in order to build the supplyability of active drug. Green and advanced continuous micro reverse process isof great significance to the strategic layout of the enterprise in the future.

ZhongshanWeifang is committed to working with domestic fine chemical leading enterprisesto promote the continuous fine chemical industry, automatic production, newproduct process development, basic chemical process improvement, from theprocess source optimization conditions, improve reaction mode, optimize unitoperation, achieve raw material consumption reduction, pollutant emissionreduction, improve the atomic economy of chemical production, to achieve cleanproduction of chemical process.

04

Solve chemical reactions with viscosity

Traditionalmicroreactors have limitations for solid-containing reactions, medium-speedreactions, and reactions in viscous systems (including polymerization). Throughthe continuous technical innovation and equipment improvement of the team, thecomplete set of micro reaction technology of Zhongshan Micro reaction hasachieved a technical breakthrough on this basis. For part of the chemicalreaction system with solid content and viscosity <2000mPa.s, stableoperation can be achieved.

05

High throughput microreactor, Reduce the investment of micro reactionequipment

Due to the thin section and small volume of the flow passage, the productioncapacity of a single set of equipment of the industrial micro-reactor isultimately limited. At present, Zhongshan Zhi 'an has been able to provide abatch of silicon carbide micro-reactor with a volume of >3L/ piece ofcorrosion-resistant alloy industrial micro-reactor and a volume of >2L/piece. Taking a nitrification reaction as an example, the reaction time takes 1minute to complete the transformation. If the flux needs to be 15000m3/ year(24000 tons/year), the liquid holding capacity of the complete set of equipmentneeds to be 35L. With ZSMR microreactor, 10~20 modules can be adopted inseries, covering an area of only 12m2, to realize unmanned automatedproduction.