In recent years, with the introduction of centralized procurement and other medical policies, the clinical development and regulatory review process of innovative drugs have been continuously optimized, which has encouraged the development of innovative drugs, making the research and development of original drugs the focus of China's drug research and development industry. At present, major domestic pharmaceutical enterprises have also turned their attention from generic drugs to innovative drugs.

From August 2 to 3, the China Pharmaceutical developer conference was held in Hangzhou. Domestic drug developers, innovators and technical service partners participated in the event, sharing and exchanging advanced experience and the latest technology from the industry development trend, R & D hotspots, development ideas and other focuses, so as to improve the overall research level of Chinese drug development and CMC. Zhongshan Zhian Chemical Technology Co., Ltd., as a well-known domestic pharmaceutical continuous flow synthesis equipment enterprise, was invited to participate in the conference.

About ZSMR

ZSMR (hereinafter referred to as Zhongshan micro reactor) is a new generation micro reactor technology innovation company with rich experience in chemical synthesis. Since 2015, Zhongshan micro reactor has been engaged in the research of micro reactor and synthesis technology, and combined with domestic well-known scientific research institutes and advanced equipment enterprises to focus on the practice and research of linear flow constant flow metering pump, 3D printing high-pressure corrosion-resistant micro reactor, high-throughput silicon carbide micro reactor and micro reactor process technology transformation with existing equipment and manufacturing technology.

At present, it has served a number of well-known domestic pharmaceutical, pesticide and fine chemical enterprises, realized industrial micro reaction process technology transformation, helped enterprises save energy and reduce consumption, reduce personnel dependence, save land resources, layout the market in advance and avoid investment risks.

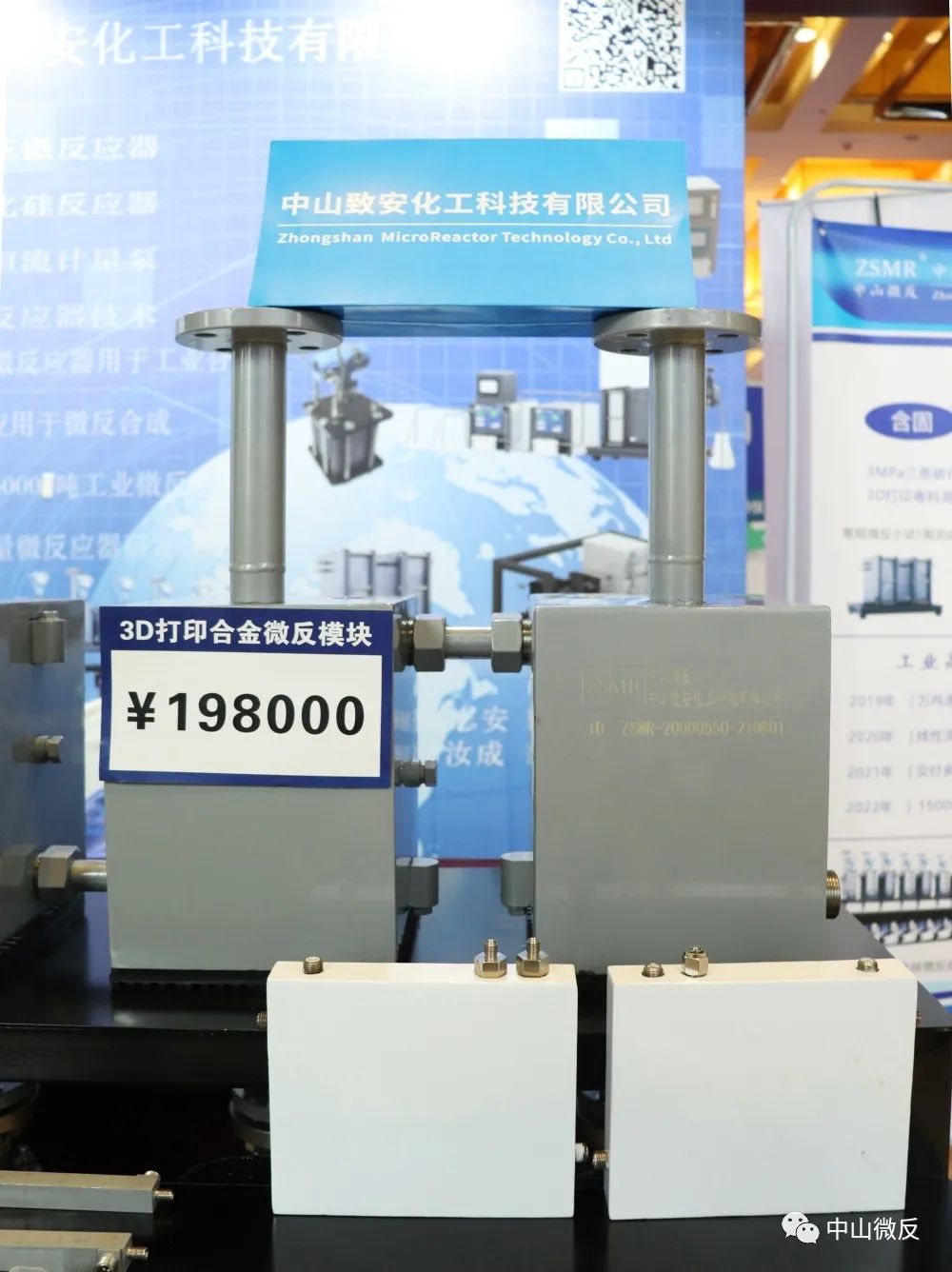

3D printing high pressure corrosion resistant micro reactor

The 3D printing high-pressure corrosion-resistant micro reactor is made of C276, ni625 and other alloy materials, which has many characteristics such as strong corrosion resistance, good mass and heat transfer effect, good temperature control effect and year-on-year amplification. The material flux of each set can reach 10000-30000 tons, and the maximum pressure can be 20MPa. In addition, the single piece liquid holding capacity of this 3D printing high-pressure corrosion-resistant micro reactor is 2L, which is the largest 3D printing reactor in China.

It is worth mentioning that 3D printing technology with microchannel reactor solves the awkward situation of "structural design without industrial products" of micro reactor. In addition, since the 3D printing high-pressure corrosion-resistant micro reactor was put into use, its yield, conversion rate and benefit have exceeded other synthesis equipment, and the three wastes and energy consumption are far lower than other synthesis equipment. In the long run, the cost of this micro reaction technology and the cost generated in the later stage are far lower than the cost of traditional chemical equipment.

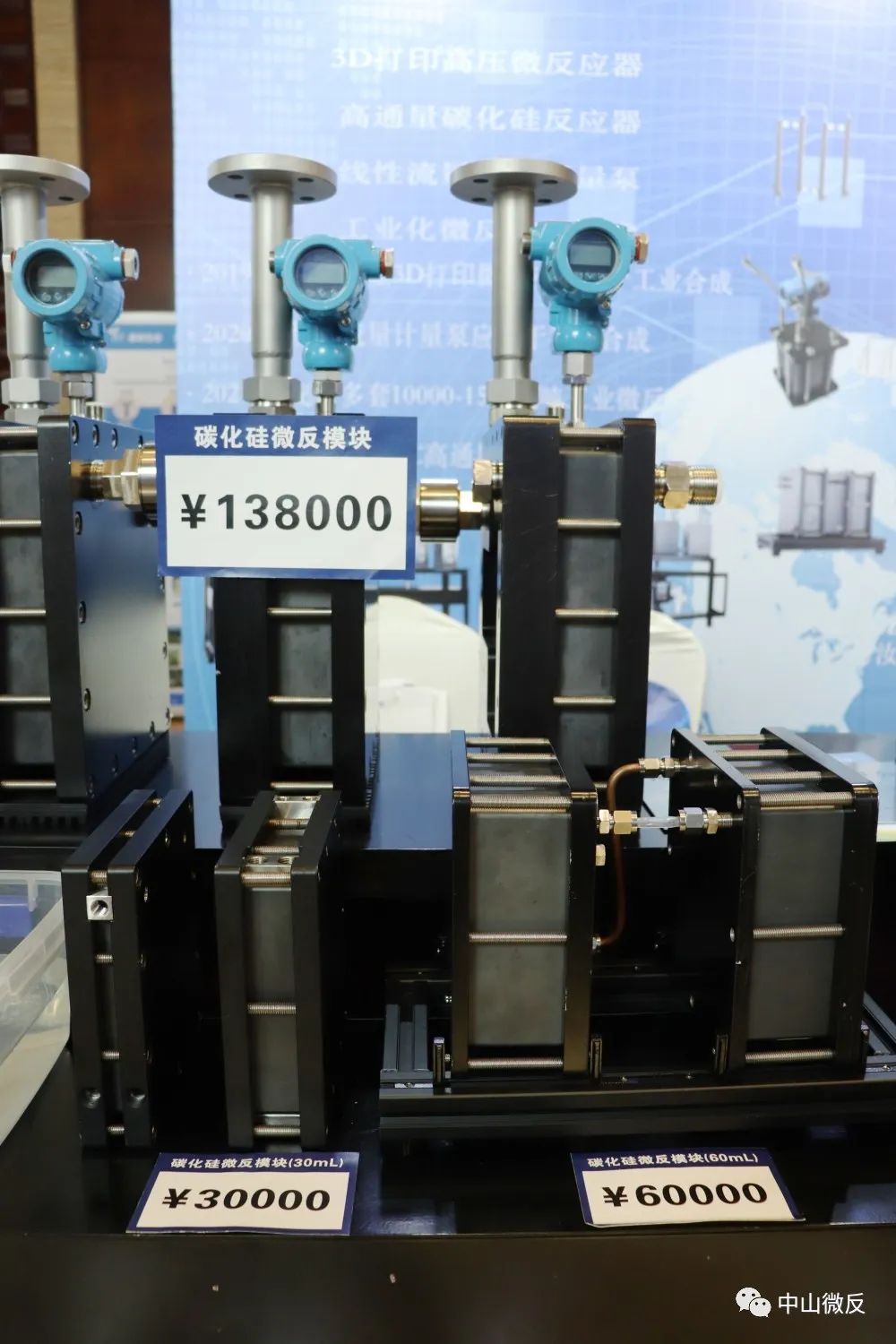

High flux silicon carbide micro reactor

The high flux silicon carbide micro reactor is made of SSIC silicon carbide, which has the characteristics of corrosion resistance, high temperature resistance, high strength, good thermal conductivity and impact resistance. The material flux of this high-throughput silicon carbide micro reactor is 10000-20000 tons per set, the liquid holding capacity of a single piece is 0.2-3l, and the pressure bearing capacity is 4MPa.

Linear flow constant flow metering pump

ZSMR linear flow constant flow metering pump adopts 316L, Hastelloy and other materials. The linear flow constant flow metering pump can reach 5ml-30l / min, the structure determines the performance, 3% pulse, linear flow, 0.1% - 0.3% instantaneous deviation. Its bearing capacity is high, and the pressure range is 0-10mpa; The plunger is made of zirconia, which has good wear resistance and oxidation resistance.

This linear flow constant flow metering pump is the power system of continuous flow equipment, the golden partner and the important guarantee of high product yield. It is one of the most accurate plunger pumps in China.